SAP Barcoding Knowledge and Information

SAP is the leader in Enterprise Resource Planning (ERP) software, which facilitates and automates data management like inventory and assets, and streamlines warehouse operations and business workflows. BCC Distribution’s mobility, barcode and RFID automation solutions further optimize SAP software and a business’s day-to-day inventory operations while helping you meet your customer demands and achieve long-term business goals. BCC Distribution combines SAP-certified software and services, with certified hardware such as barcode scanners, barcode printers, and RFID technology. When optimized for your specific business, SAP ERP (S/4HANA and ECC 6.0) is a powerful tool to organize data collection strategies, provide information visibility, and review operational analytics to improve workflows and task completion.

At BCC Distribution, we provide end-to-end SAP barcoding solutions, which include a centralized hub of SAP applications, information, and updates. Not only do we provide comprehensive SAP-certified barcoding systems to fit our client’s unique business needs, but we strive to stay abreast to the latest SAP developments as well as our customer’s future roadmaps for SAP migration and upgrade.

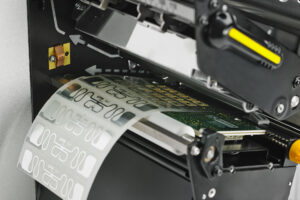

In our SAP Barcoding Knowledge Base, BCC Distribution works to continuously post the latest about our SAP software solutions and related barcoding technology. Solutions such as TranASAP and QuickPrint are our SAP-certified and pre-configured SAP integrated software solutions that simplify data collection and barcode printing respectively. Our centralized SAP software and barcoding knowledge repository makes it easier to find answers and learn more about possible SAP applications that align with your requirements.

We also continually discuss and co-present key updates about these barcoding and RFID hardware solutions in partnership with the leading names in barcode and RFID automation technology, such as Zebra Technologies, Seagull Scientific, Ivanti, Honeywell, SOTI and more.